Description

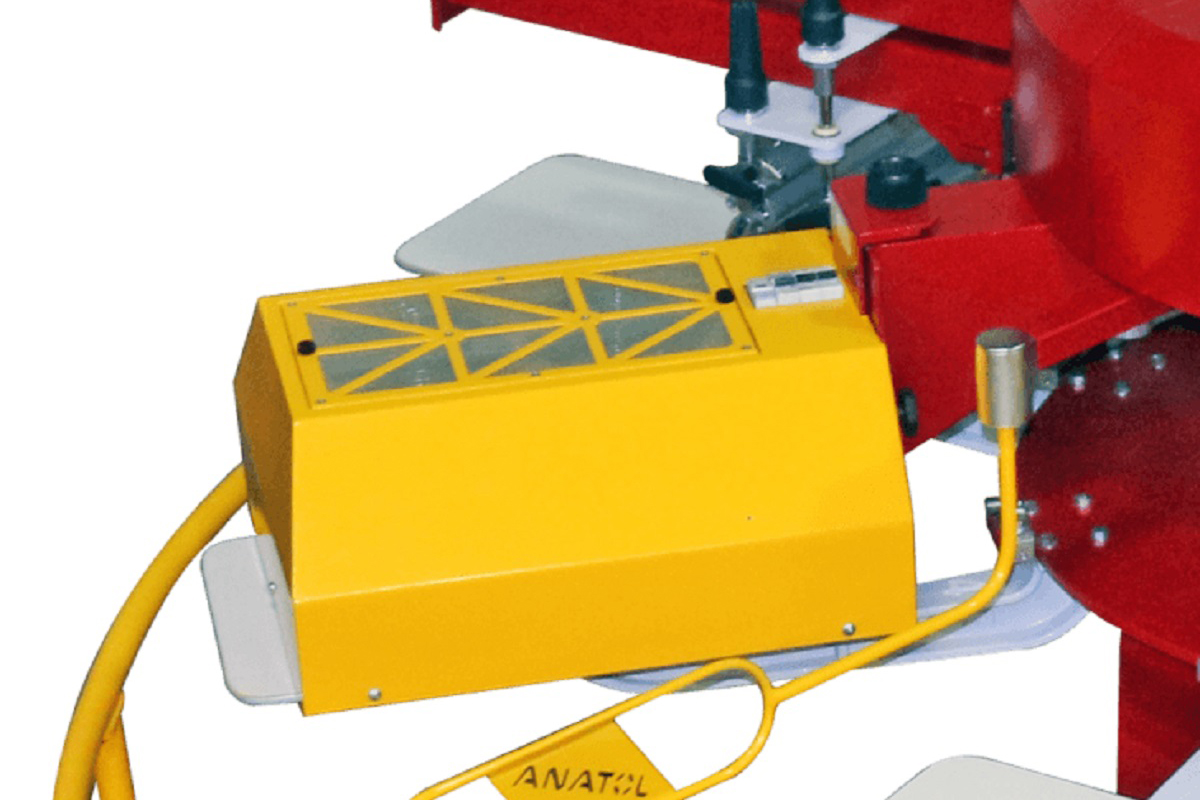

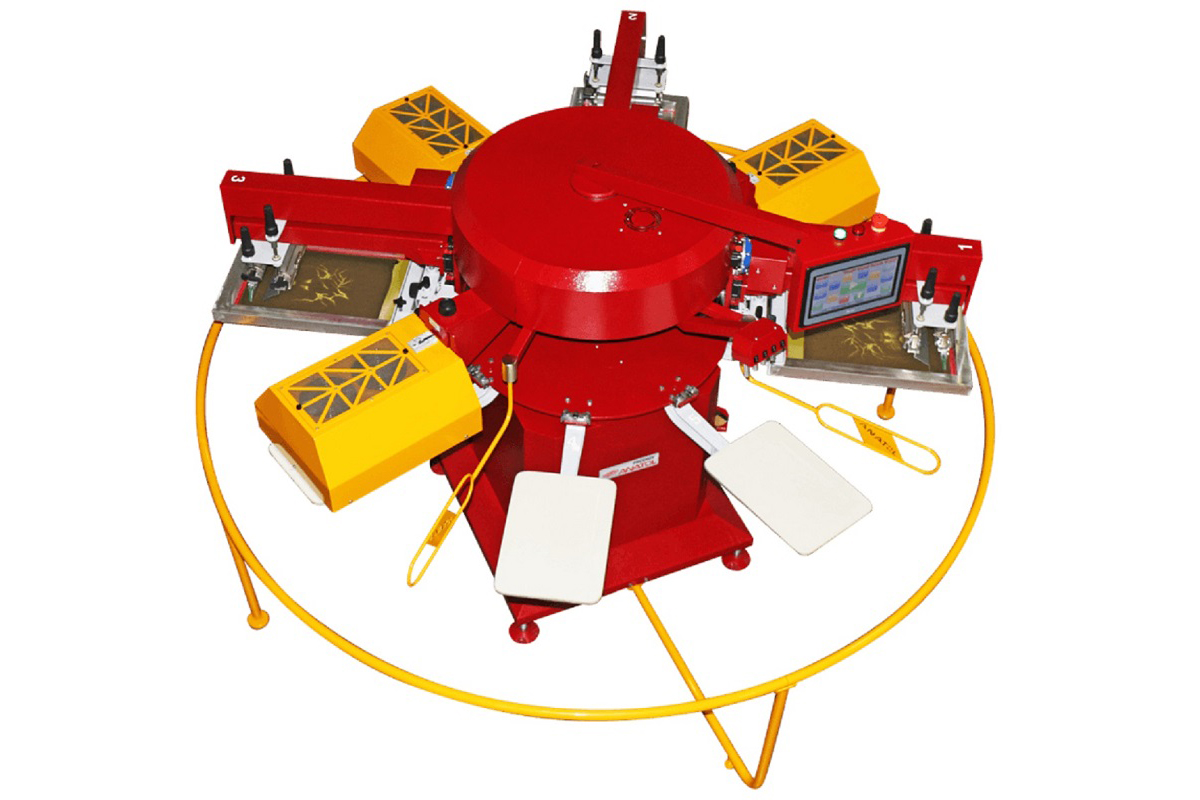

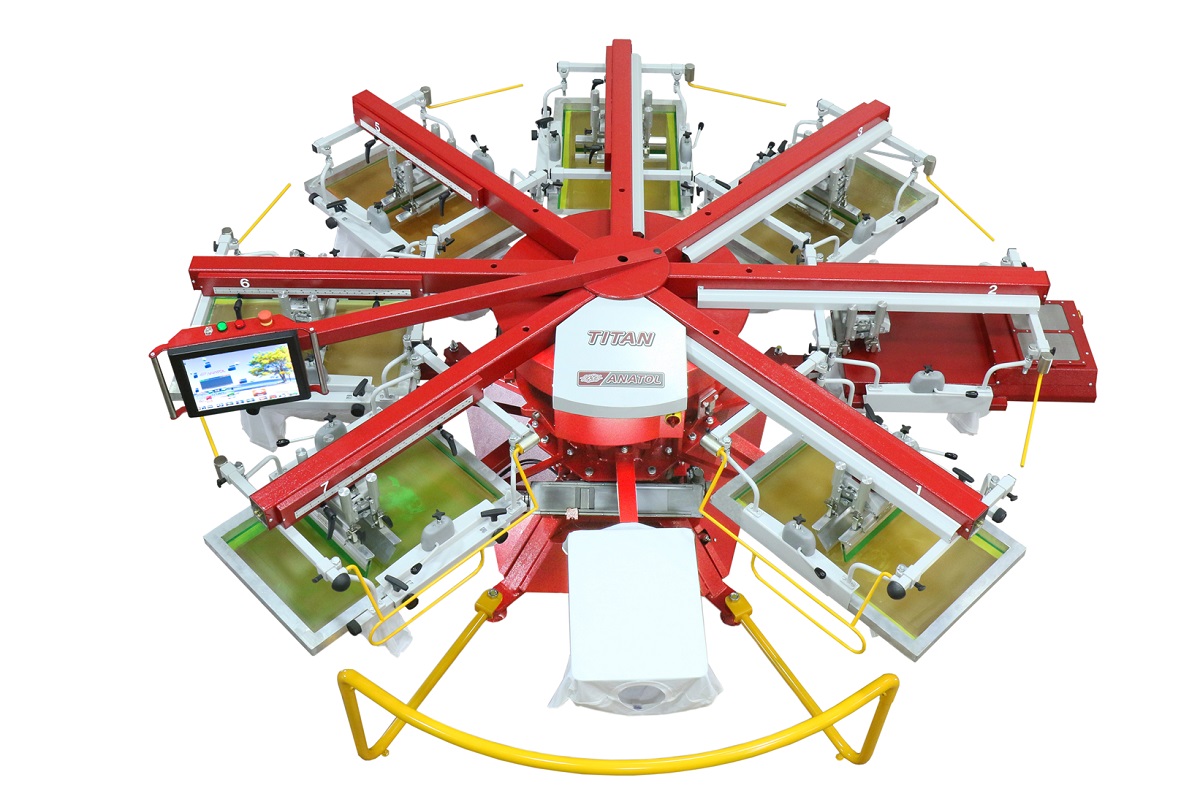

Not just for tags anymore! The new and improved Prodigy is Anatol’s all-servo automatic small format printing press, perfect for smaller substrates like shirt tags, sleeves, tote bags, koozies and other promotional products. Capable of printing up to 1700 pieces per hour, the Prodigy is equipped with built-in forced air quartz flashes, that feature air flow control to cure a wide variety of inks and substrates quickly and efficiently. The press is controlled via a touchscreen powered by Anatol Equipment’s exclusive Aries 2 operating system. The servo-driven indexer, lift and print heads provide a smooth, consistent print job every time. A built-in laser alignment system comes standard, making pallet location adjustments and apparel alignment quick, easy and reliable. The Prodigy is available with up to 10 stations, and prints in 2 to 4 colors, with a maximum image size of 10” x 12”.

Standard features

Touchscreen Controls

- 15” touchscreen with Aries 2 operating system

- Easy to program controls save on set-up time

- The screen displays the number of prints (dozen) and speed (pcs/hr)

- Adjustable dwell times allow for adjustments to cycling speed and cool-down time

- Digital stroke length adjustment

- Save/recall job settings

Print Heads

- Servo-electric print heads

- Independent flood/print speed control

- Multiple print strokes (1 – 9) per head

- Quick-release squeegee and flood bar for fast changeover

- Skip-Shirt sensor automatically detects shirts

- Rear screen holders with mechanical clamps allow for quick and easy loading of screens

Tool-less Adjustment

- Independent squeegee/flood bar angle adjustments with single-handed adjustments of 0º-30º, at increments of 5º

- Three-point micro-registration (front-to-back, left-to-right and rotational movement) available for multicolor models

Construction

- Servo indexer

- Heavy-duty rolled steel frame supports smooth, high speed production cycles

- Small footprint accommodates tight spaces

Safety Systems

- Industry’s best safety bars provide a barrier protecting operators from rotating carousel

- Unique safety system on load/unload station

Laser Alignment System

- Laser alignment system for quick and easy apparel alignment

- Four independently-adjustable straight red lasers

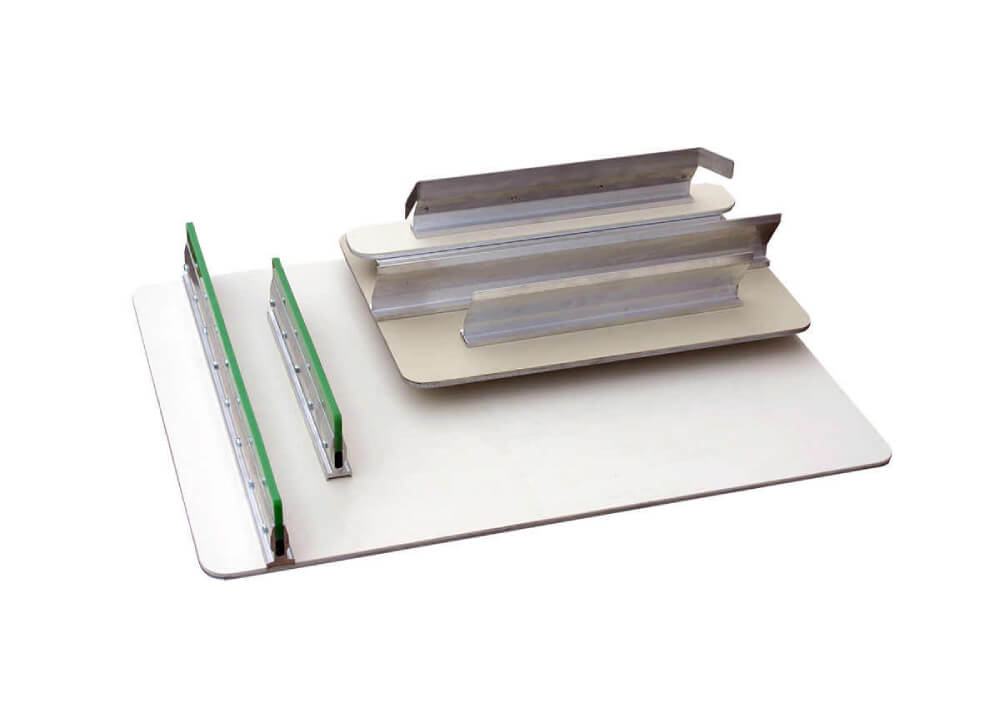

Pallets

- Slide style pallets, precisely as on our bigger automatic presses, with tool-less locking and unlocking for easy pallet changeover and adjustment

- Rubber-coated aluminum pallets

- Standard 9.1” x 12” pallets included (for machines with 8″ x 8″ print area)

- Standard 11″ x 16.3″ pallets included (for machines with 10″ x 12″ print area)

- Other pallets available upon request

Prodigy Specifications

| Stations/Colors | Maximum Print Area | Maximum Screen Size | Standard Pallet Size | Diameter | Weight | Height | Minimum Door Size Standard | # of Quartz Flashes/Power | Electrical Requirements |

|---|---|---|---|---|---|---|---|---|---|

| 6/2 | 8” x 8” 20cm x 20cm |

12” x 17.5” 31cm x 45cm |

9.1” x 12” 23cm x 31cm |

5’ 3” 160cm |

661lbs 300kg |

5’ 11” 180cm |

4’ 1” 125cm |

2 2 x 1750W |

1 Ph, 22 A, 208-240V, 50-60Hz |

| 8/3 | 8” x 8” 20cm x 20cm |

12” x 17.5” 31cm x 45cm |

9.1” x 12” 23cm x 31cm |

5’ 7” 170cm |

771lbs 350kg |

5’ 11” 180cm |

4’ 7” 140cm |

3 3 x 1750W |

1 Ph, 30 A, 208-240V, 50-60Hz |

| 10/4 | 8” x 8” 20cm x 20cm |

12” x 17.5” 31cm x 45cm |

9.1” x 12” 23cm x 31cm |

6’ 5” 195cm |

5’ 11” 180cm |

5’5″ 165cm |

4 4 x 1750W |

1 Ph, 45 A, 208-240V, 50-60Hz 3 Ph, 31 A, 208-240V, 50-60Hz |

| Stations/Colors | Maximum Print Area | Maximum Screen Size | Standard Pallet Size | Diameter | Weight | Height | Minimum Door Size Standard | # of Quartz Flashes/Power | Electrical Requirements |

|---|---|---|---|---|---|---|---|---|---|

| 6/2 | 10” x 12” 25cm x 30cm |

17” x 24” 43cm x 61cm |

11” x 16.3” 28cm x 41.4cm |

7’ 3” 220cm |

1102lbs 500kg |

5’ 11” 180cm |

5’ 7” 170cm |

2 2 x 4000W |

1 Ph, 47 A, 208-240V, 50-60Hz 3 Ph, 27 A, 208-240V, 50-60Hz |

| 8/3 | 10” x 12” 25cm x 30cm |

17” x 24” 43cm x 61cm |

11” x 16.3” 28cm x 41.4cm |

7’ 9” 235cm |

1323lbs 600kg |

5’ 11” 180cm |

6’ 3” 190cm |

3 3 x 4000W |

1 Ph, 68 A, 208-240V, 50-60Hz 3 Ph, 39 A, 208-240V, 50-60Hz |

| 10/4 | 10” x 12” 25cm x 30cm |

17” x 24” 43cm x 61cm |

11” x 16.3” 28cm x 41.4cm |

8’ 6” 260cm |

6’1″ 185cm |

7’3″ 220cm |

4 4 x 4000W |

1 Ph, 90 A, 208-240V, 50-60Hz 3 Ph, 50 A, 208-240V, 50-60Hz |

Premium service that will exceed your expectations

Customer Service and Support are a way of life at Anatol Equipment. We strive to improve our service to keep your equipment running like the day you had it installed. This is our commitment to every customer. Two-year limited warranty.

Anatol Support Contacts

We are always ready to help!

847-582-1825Warranty Registration

Please complete all form fields. By submitting this form you agree to all Warranty Terms & Conditions. You must complete a form for EACH Anatol machine you wish to register.

Questions & Answers

Need help? Have Questions? Want answers?

We’ve compiled a list of commonly asked questions our customers ask most frequently. You’ll find your answers here.