Description

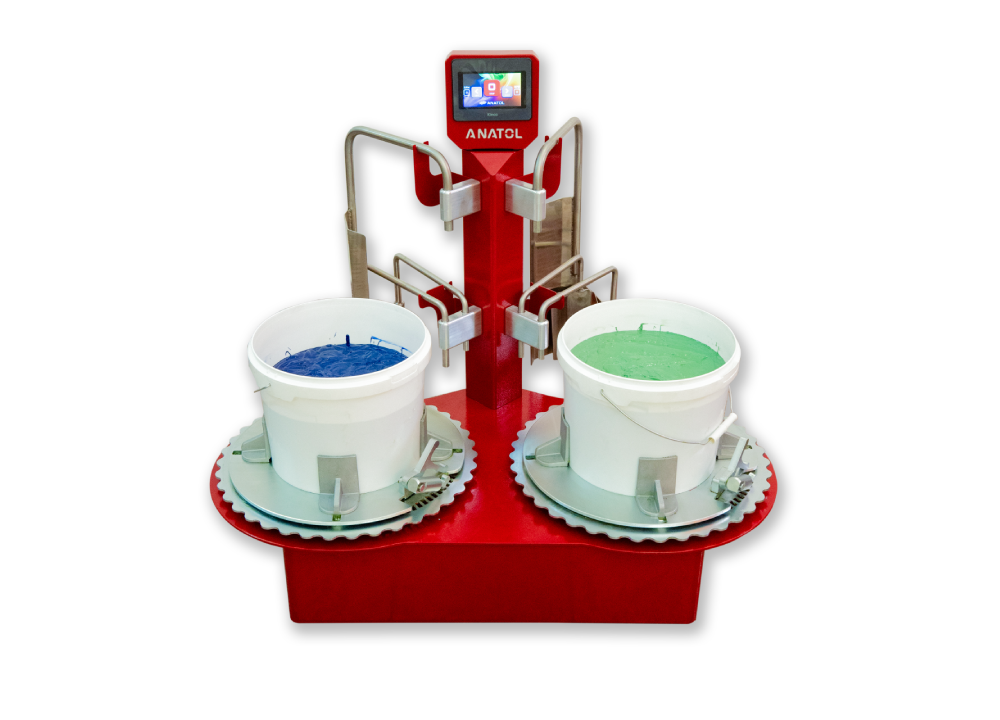

An ink mixer is a vital piece of equipment in a professional screen printing shop. The Anatol Formulator Double Screen Printing Ink Mixer is ideal for mixing plastisol or water-based inks, for adding pigments such as glitters and fluorescents to bases, and for ensuring thorough blending of reducers and other modifiers. The self-centering feature automatically adjusts the Formulator to hold a wide variety of ink containers , from 1 quart up to 6 gallons, two containers at a time! The mixer’s special blade configuration with “lift and roll” movement provides gentle, thorough mixing without splash-up or air bubbles, and prevents ink from settling in the sides or bottom of the container. The Formulator offers fixed and variable speed options, and can rotate either clockwise or clockwise.

Standard Features

Construction

- Variable speed AC electric motor

- Heavy-duty steel construction

- Self-centering clamp

- Easily-adjustable touchscreen angle for convenient access

Operation

- Easy-to-use touchscreen control panel

- Change mixing direction (clockwise, counterclockwise)

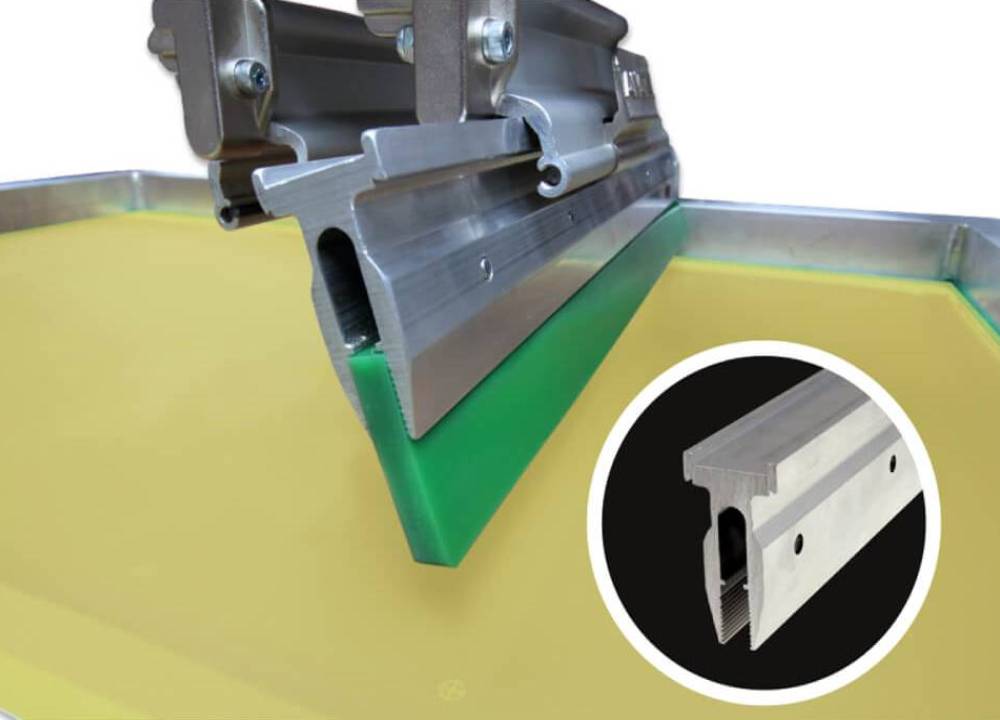

- Quick and easy changeover for different blade sizes

- Set mixing speed, time and direction and quickly save and recall up to 6 different programs

Ink Mixer Double Specifications

| MODEL | WEIGHT | INK VOLUME | OUTER DIMENSIONS WXDXH | ELECTRICAL REQUIREMENTS |

|---|---|---|---|---|

| DOUBLE MIXER | 207lbs (94 kg) |

up 1/4G (0.95L) x2 to 6G (22.7L) x2 |

38.2” x 26.1” x 33.4” 970mm x 663mm x 847.5 mm |

1 Phase, 110V, 15A 1 Phase 208-240V, 13A |

Premium service that will exceed your expectations

Anatol Support Contacts

We are always ready to help!

847-582-1825Warranty Registration

Please complete all form fields. By submitting this form you agree to all Warranty Terms & Conditions. You must complete a form for EACH Anatol machine you wish to register.

Questions & Answers

Need help? Have Questions? Want answers?

We’ve compiled a list of commonly asked questions our customers ask most frequently. You’ll find your answers here.